Product Description

Hydraulic gear pump hunting penis gear shift knob plastic worm bicycle set hob machine fixed frame dc motor helical prices stainless steel swing planetary

Application of Hydraulic gear

Hydraulic gears are used in a wide variety of applications, including:

- Construction equipment: Hydraulic gears are used in construction equipment, such as excavators, cranes, and loaders, to provide power and control.

- Agriculture: Hydraulic gears are used in agricultural equipment, such as tractors, harvesters, and combines, to provide power and control.

- Manufacturing: Hydraulic gears are used in manufacturing equipment, such as presses, stamping machines, and conveyors, to provide power and control.

- Mining: Hydraulic gears are used in mining equipment, such as drills, loaders, and conveyors, to provide power and control.

- Aerospace: Hydraulic gears are used in aerospace equipment, such as jet engines, helicopters, and spacecraft, to provide power and control.

Hydraulic gears are a versatile and reliable component that can be used in a variety of applications. They offer a number of advantages over other types of gears, including high torque, low speed, and quiet operation.

Here are some of the benefits of using hydraulic gears:

- High torque: Hydraulic gears can transmit high torque, which is necessary for applications where a lot of force needs to be applied.

- Low speed: Hydraulic gears can operate at a low speed, which is necessary for applications where noise and vibration need to be minimized.

- Quiet operation: Hydraulic gears operate quietly, which is important for applications where noise is a concern.

- Versatility: Hydraulic gears can be used in a variety of applications.

If you need a component that can transmit high torque and operate at a low speed, then a hydraulic gear may be the right solution for you.

Here are some specific examples of how hydraulic gears are used in different applications:

- Construction equipment: Hydraulic gears are used in construction equipment to provide power and control for a variety of tasks, such as lifting heavy loads, moving materials, and operating hydraulic cylinders.

- Agriculture: Hydraulic gears are used in agricultural equipment to provide power and control for a variety of tasks, such as harvesting crops, planting seeds, and operating hydraulic cylinders.

- Manufacturing: Hydraulic gears are used in manufacturing equipment to provide power and control for a variety of tasks, such as stamping metal, cutting metal, and operating hydraulic cylinders.

- Mining: Hydraulic gears are used in mining equipment to provide power and control for a variety of tasks, such as drilling for ore, loading ore CHINAMFG conveyor belts, and operating hydraulic cylinders.

- Aerospace: Hydraulic gears are used in aerospace equipment to provide power and control for a variety of tasks, such as controlling the movement of jet engines, helicopters, and spacecraft.

Hydraulic gears are a vital component in many different types of machinery. They provide power and control in a variety of applications, from construction equipment to aerospace.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Worm Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can planetary gears be used in high-torque applications?

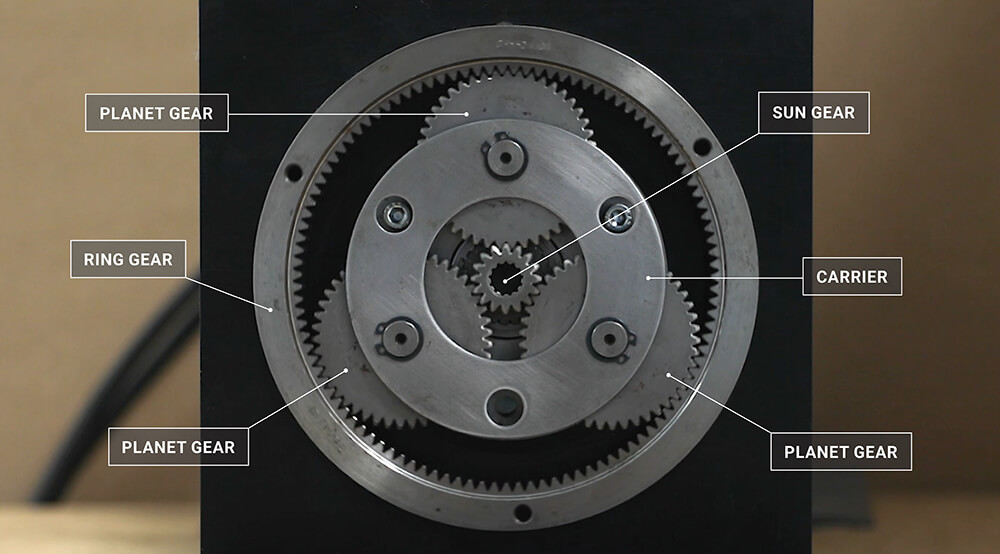

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

How do planetary gears handle variations in direction and torque transmission?

Planetary gears are versatile mechanisms that can effectively handle variations in direction and torque transmission. Let’s explore how they achieve this:

- Direction Reversal:

Planetary gears are capable of transmitting torque in both forward and reverse directions. By changing the input and output connections, the direction of rotation can be reversed without the need for additional components or complex mechanisms. This makes planetary gears well-suited for applications where frequent changes in direction are required, such as automotive transmissions.

- Torque Amplification and Reduction:

One of the notable characteristics of planetary gears is their ability to amplify or reduce torque depending on the arrangement of gear components. Let’s consider a basic arrangement with a sun gear, planet gears, and a ring gear:

- Torque Amplification:

When the sun gear is the input and the ring gear is the output, the planet gears rotate on their own axes while also revolving around the sun gear. This arrangement allows for torque amplification, meaning the output torque can be higher than the input torque. This is particularly useful in applications where higher torque is required, such as heavy machinery or power transmission systems.

- Torque Reduction:

Conversely, by fixing the ring gear and using the sun gear as the output, the planet gears rotate on their own axes while also revolving around the fixed ring gear. In this configuration, the output torque is lower than the input torque, enabling torque reduction. This can be advantageous in applications where torque needs to be reduced, such as speed reduction systems or precision machinery.

- Combination of Gear Stages:

Planetary gears can be combined into multiple stages, with each stage having its own set of sun gears, planet gears, and ring gears. This arrangement allows for further variations in torque transmission. By connecting the output of one stage to the input of another, the torque can be further amplified or reduced, providing flexibility in power transmission systems.

- Custom Gear Ratios:

By selecting the appropriate sizes and numbers of teeth for the sun gears, planet gears, and ring gears, custom gear ratios can be achieved in planetary gear systems. This allows for precise control over torque transmission and enables the adaptation of the gear arrangement to specific application requirements.

In summary, planetary gears handle variations in direction and torque transmission through their ability to reverse direction without additional components, torque amplification or reduction based on gear arrangement, combination of multiple gear stages, and the ability to achieve custom gear ratios. These features make planetary gears a versatile choice for a wide range of applications requiring efficient and flexible power transmission.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-11-01