Product Description

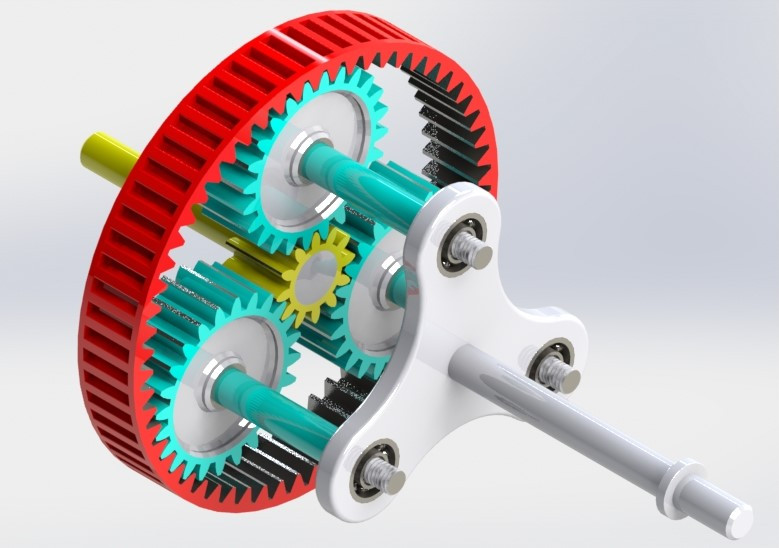

| Product type | Sintered metal parts / Planetary Sun Drive Spur Gea |

| Material | Stainless steel,Steel(Iron,)Brass,Copper (According to product design requirements) |

| Tolerance | ±0.01mm |

| Surface Treatment | As your requirement |

| Application | Tool industry,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, light industry products, sanitation machinery, etc. |

| Shape | Any other material and dimension depends on customers’ demand. |

| QC system | 100% inspection before shipment |

| Returned Goods Managing | With quality problem or deviation from drawings |

| Warranty | Replacement at all our cost for rejected products |

| Payment terms | T/T at sight, Paypal, Western Union,etc. |

| Lead time | 7-15 working days as usual,It will based on the detailed order quantity. |

| Why Choose Us |

1. We have professional powder metallurgy production equipment and team;

2. We can accompany customers to develop products;

3. Just send an idea that you want to try, you don’t even need to know what powder metallurgy;

4. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

5. Our team will evaluate your inquiry and provide our offer within next 1~3 working days.

| Order Process |

1. You send us drawing or sample.

2. We carry through project assessment.

3. We give you our design for your confirmation.

4. We make the sample and send it to you after you confirmed our design.

5. You confirm the sample then place an order and pay us deposit.

6. We start producing.

7. When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers.

8. Trade is done, thank you!!

Additional Capabilities CAD Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering

| Product Show |

| Some Parts We Manufacture |

Self-Lubricated Bushing

Structural Parts

Gears

| About Us |

DERYOUNG Technology company is a professional metal parts manufacturer, which with more than 20 years of experience in the development and production of sintered metals. Each year we produce more than 100 million premium sintered metal parts for our customers. We are mainly produce oil bearing, gear, and metal parts. We support our customers in the design and material selection of sintered parts, providing the best solution for your applied parts through our specialized equipment compression molds, furnaces, handling, sizing, deburring and impregnation processes.

| Design Tips: Powder Metallurgy Gears |

1. Radius > 0.25 mm is required to manufacture the die;

2. Helical teeth should feature a helical angle < 30º in order to limit side pressure on the punches;

3. Introduction of a draft angle > 5º in the upper diameter reduce the tooling cost;

4. The distance between tooth root and central hub diameter must be: > 3 mm (Robust Tooling).

If you want to know more about the product, please send us a message.

| The Powder Metallurgy Manufacturing Process |

| FAQ |

| Q: How can I get the quotation? |

| A: Please send us information for quote: drawing, material, weight, quantity and request,w can accept PDF, ISGS, DWG, STEP file format. If you don’t have drawing, please send the sample to us,we can quote based on your sample too. |

| Q: What’s your MOQ? |

| A: In general 1000pcs,but can accept low quantity in some special conditions. |

| Q: Do you provide samples ? is it free or extra ? |

| A: Yes, we could offer the sample for free charge but do not pay the cost of freight. |

| Q: What about the leading time for mass production? |

| A: Honestly, it depends on the order quantity. Normally, 15 days to 20 days after your deposit if no tooling needed. |

| Q: What if the parts are not good? |

| A: We can guarantee good quality,but if happened,please contact us immediately, take some pictures, we will check on the problem,and solve it asap. |

| Q: What is your terms of payment ? |

| A: Payment=1000USD, 30% T/T in advance ,balance before shippment |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

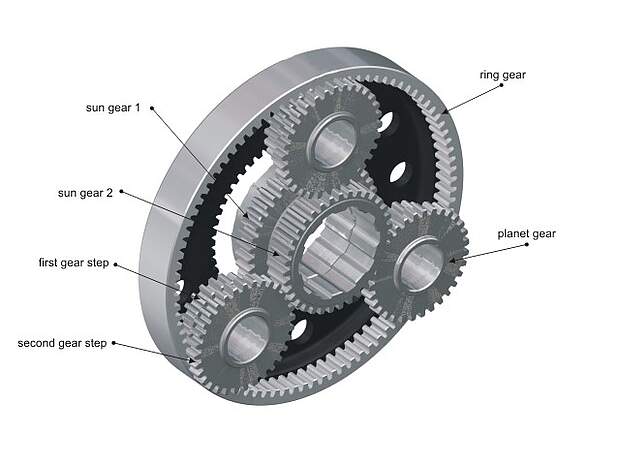

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

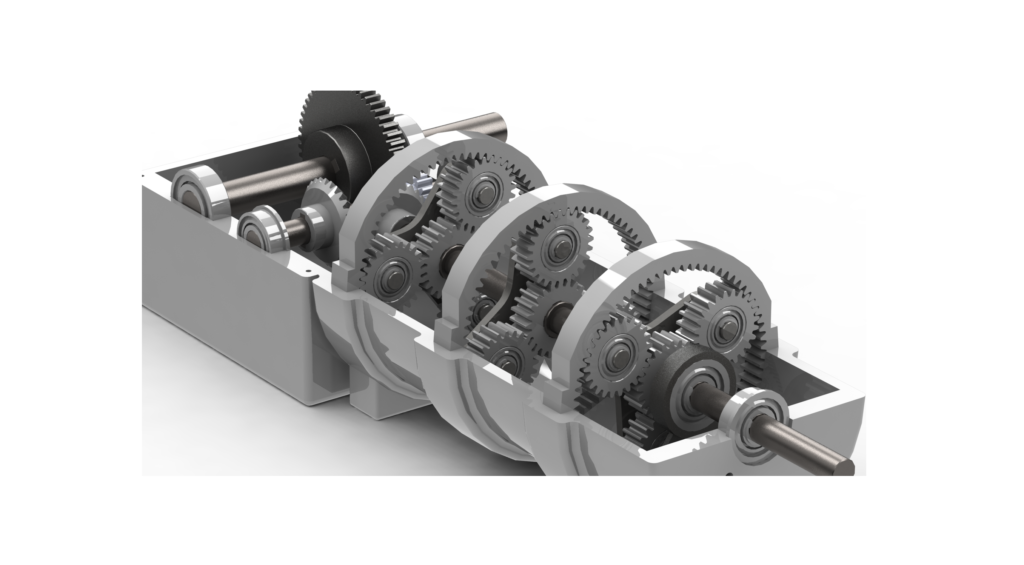

What industries commonly use planetary gears in their applications?

Planetary gears find applications in a wide range of industries and mechanical systems. Let’s explore some of the industries that commonly utilize planetary gears:

- Automotive Industry:

The automotive industry extensively uses planetary gears in various applications. Planetary gears are commonly found in automatic transmissions, where they enable smooth gear shifting, provide different gear ratios, and transmit torque efficiently. They are also used in differential systems, allowing wheels to rotate at different speeds while maintaining power distribution.

- Robotics and Automation:

Planetary gears play a crucial role in robotics and automation systems. They are employed in robotic joints and actuators to provide precise motion control, compact size, and high torque transmission. Planetary gears enable robotic arms to move accurately and handle heavy loads, making them essential components in industrial robots and robotic manipulators.

- Aerospace and Aviation:

The aerospace and aviation industries utilize planetary gears in various applications. They are used in aircraft landing gear systems, where they provide reliable torque transmission and compact design. Planetary gears are also employed in aircraft engine systems, helicopter rotor systems, and satellite mechanisms due to their efficiency, high torque capacity, and ability to operate in space-restricted environments.

- Power Generation:

Planetary gears are utilized in power generation equipment, including wind turbines and hydroelectric generators. In wind turbines, planetary gears enable the conversion of low-speed rotor rotation to high-speed generator rotation, ensuring efficient power generation. They are also employed in hydroelectric generators to transmit power from turbines to electrical generators, providing gear reduction and torque amplification.

- Industrial Machinery:

Planetary gears are widely used in industrial machinery applications. They are found in heavy-duty machinery such as mining equipment, construction machinery, and material handling systems. Planetary gears provide high torque transmission, compactness, and durability, making them suitable for handling demanding tasks in industrial environments.

- Marine and Shipbuilding:

The marine and shipbuilding industries employ planetary gears in various marine propulsion systems. They are used in marine engines, propeller systems, and thrusters. Planetary gears provide efficient power transmission, speed control, and compact design for propulsion systems in vessels ranging from small boats to large ships.

- Medical Equipment:

In the medical field, planetary gears are utilized in various equipment and devices. They are found in medical imaging systems like CT scanners and MRI machines, providing precise motion control and reducing image distortion. Planetary gears are also used in surgical robots and medical devices that require compact size, high torque, and accurate positioning.

These are just a few examples of the industries that commonly use planetary gears in their applications. The versatility, efficiency, and compactness of planetary gears make them suitable for a broad range of industries where precise motion control, torque transmission, and space-saving design are essential requirements.

editor by CX 2024-03-26