Product Description

| 810-35199-6651 | Middle bridge basin Angle tooth (37/12) |

| Q50 0571 2 | 6.3 * 32 – ST – A4C cotter pin |

| 712W35125-0571 | Differential adjustment nut |

| 810W93420-0183 | Tapered roller bearing 32571 |

| MQ6571163416 | Differential housing screw |

| 812-35105-0194 | Differential housing |

| 810W9571-5718 | Differential planetary wheel gasket |

| 710W55711- | |

| Q43745 | Retainer ring |

| 810-35199-6598 | Rear axle basin Angle teeth (12/37) |

| 810-35301-6116 | Rear axle main housing reduction assembly |

| WG7117329065 | Rear axle input flange |

| WG7117329018/329001 | Rear axle input oil seal |

| 810W35601-0040 | Bearing housing (rear axle) |

| 812-35105-0061 | Rear axle wheel difference shell |

| WG91571014 | bearing |

| WG91571571 | bearing |

| WG9981032222 | Bearing |

| WG9981032313 | Bearing |

| HR9-ZXJXLB | Steering knuckle repair kit |

| WG9100443050 | Front brake pad |

| 420HP Engine(D12.42) | ||

| VG157171050 | Rear oil seal | 1 |

| VG1246571005 | Front oil seal | 1 |

| VG260571208 | Flywheel gear ring | 1 |

| AZ1242571561 | Flywheel assembly | 1 |

| VG1246030011/12 | Connecting rod tile | 1 |

| VG1246571034/35 | Main bearing | 1 |

| AZ1246030007 | Connecting rod assembly | 6 |

| VG1246030013 | Connecting rod bolt | 12 |

| VG1246030015 | Piston assembly | 6 |

| VG1540030005 | Piston ring | 1 |

| VG1246030002 | Piston pin | 6 |

| VG1246571571 | Cylinder liner | 6 |

| D12.42-XLB | Engine repair kit | 1 |

| VG1246040571 | Cylinder pad | 6 |

| VG1246050571/22 | Intake and exhaust valve | 1 |

| VG1246 0571 1 | Valve push rod | 12 |

| VG1246 0571 1 | Valve tappet | 12 |

| VG1246060091 | Belt | 1 |

| VG1246060005 | Automatic tensioning wheel | 1 |

| VG1246060094 | Pump assembly | 1 |

| VG1246060088 | Belt | 1 |

| VG1246060051 | Fan leaves | 1 |

| VG1246070012 | Oil cooler core | 1 |

| VG1246080002 | High-pressure pipeline | 1 |

| VG1246090017 | generator | 1 |

| VG1246090002 | starter | 1 |

| VG124611571 | Turbocharger | 1 |

| VG1246130008 | Air compressor | 1 |

| VG12465716 | Fuel injector assembly | 6 |

| WG9731471571 | Steering vane pump | 1 |

| VG1246070031 | Oil filter | 2 |

| VG1540080110 | Diesel filter | 1 |

| VG | Diesel filter | 1 |

| WG9725195712/103 | air filter | 1 |

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 6months |

| Type: | Chassis |

| Certification: | ISO14001 |

| Driving System Parts: | Suspension |

| Electrical System Parts: | Lighting |

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) | |

|---|

How do you calculate the gear ratio involving sun, planet, and ring gears?

The gear ratio in a planetary gear system can be calculated by considering the number of teeth on the sun gear, planet gears, and ring gear. The gear ratio determines the relationship between the input speed and the output speed of the system. Here’s how you can calculate the gear ratio:

- Step 1: Count the Teeth:

Count the number of teeth on the sun gear (S), the planet gears (P), and the ring gear (R). These numbers represent the respective gear’s tooth count.

- Step 2: Determine the Gear Arrangement:

Identify the gear arrangement. In a simple planetary gear system, the sun gear is at the center, surrounded by planet gears, and enclosed by the ring gear.

- Step 3: Calculate the Gear Ratio:

The gear ratio (GR) can be determined using the formula:

GR = (R + P) / S

Where:

- R represents the number of teeth on the ring gear

- P represents the number of teeth on the planet gears (assuming they have the same number of teeth)

- S represents the number of teeth on the sun gear

The resulting gear ratio represents the speed relationship between the input and output of the planetary gear system. A gear ratio greater than 1 indicates a speed reduction, while a gear ratio less than 1 indicates a speed increase.

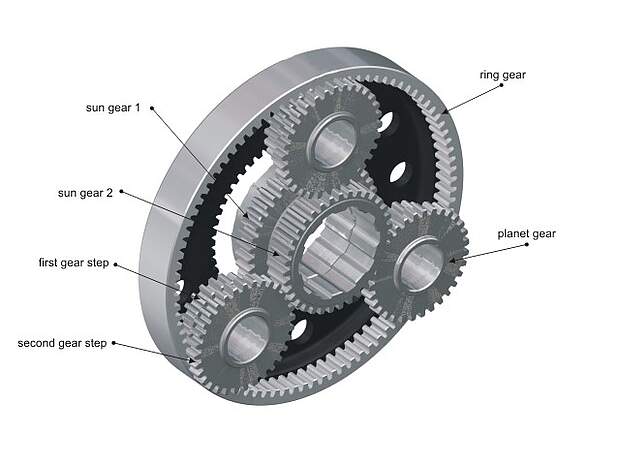

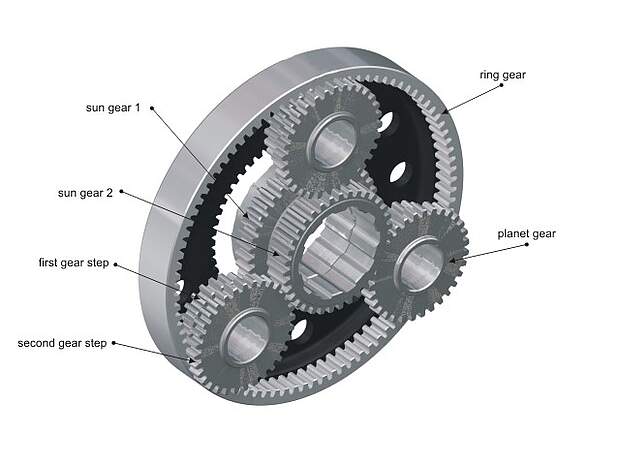

It’s important to note that in more complex planetary gear systems, where there are multiple sets of planet gears or additional gears, the calculation of the gear ratio may involve considering multiple gear stages and their respective tooth counts.

In summary, to calculate the gear ratio involving sun, planet, and ring gears, you need to count the teeth on each gear and use the formula (R + P) / S, where R is the number of teeth on the ring gear, P is the number of teeth on the planet gears, and S is the number of teeth on the sun gear. This calculation provides the gear ratio that defines the speed relationship between the input and output of the planetary gear system.

How do planetary gears handle variations in direction and torque transmission?

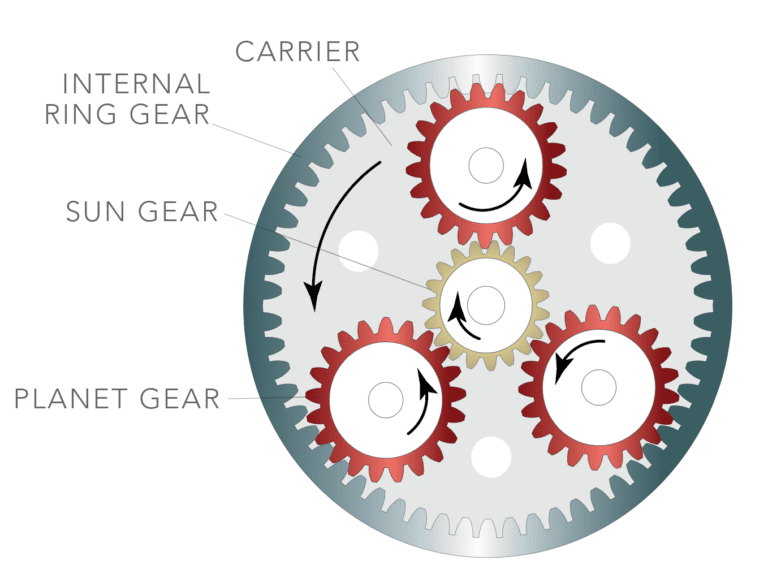

Planetary gears are versatile mechanisms that can effectively handle variations in direction and torque transmission. Let’s explore how they achieve this:

- Direction Reversal:

Planetary gears are capable of transmitting torque in both forward and reverse directions. By changing the input and output connections, the direction of rotation can be reversed without the need for additional components or complex mechanisms. This makes planetary gears well-suited for applications where frequent changes in direction are required, such as automotive transmissions.

- Torque Amplification and Reduction:

One of the notable characteristics of planetary gears is their ability to amplify or reduce torque depending on the arrangement of gear components. Let’s consider a basic arrangement with a sun gear, planet gears, and a ring gear:

- Torque Amplification:

When the sun gear is the input and the ring gear is the output, the planet gears rotate on their own axes while also revolving around the sun gear. This arrangement allows for torque amplification, meaning the output torque can be higher than the input torque. This is particularly useful in applications where higher torque is required, such as heavy machinery or power transmission systems.

- Torque Reduction:

Conversely, by fixing the ring gear and using the sun gear as the output, the planet gears rotate on their own axes while also revolving around the fixed ring gear. In this configuration, the output torque is lower than the input torque, enabling torque reduction. This can be advantageous in applications where torque needs to be reduced, such as speed reduction systems or precision machinery.

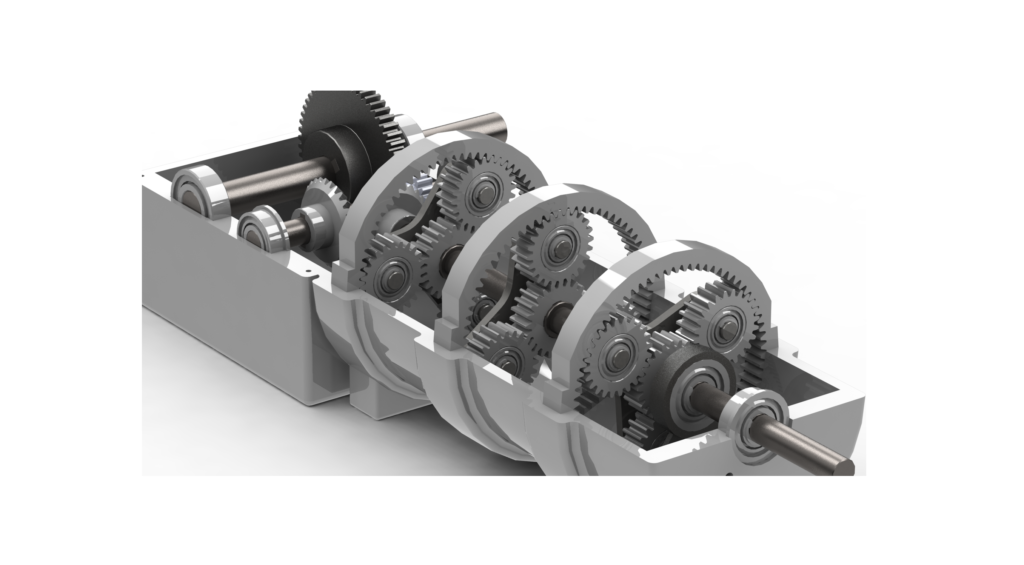

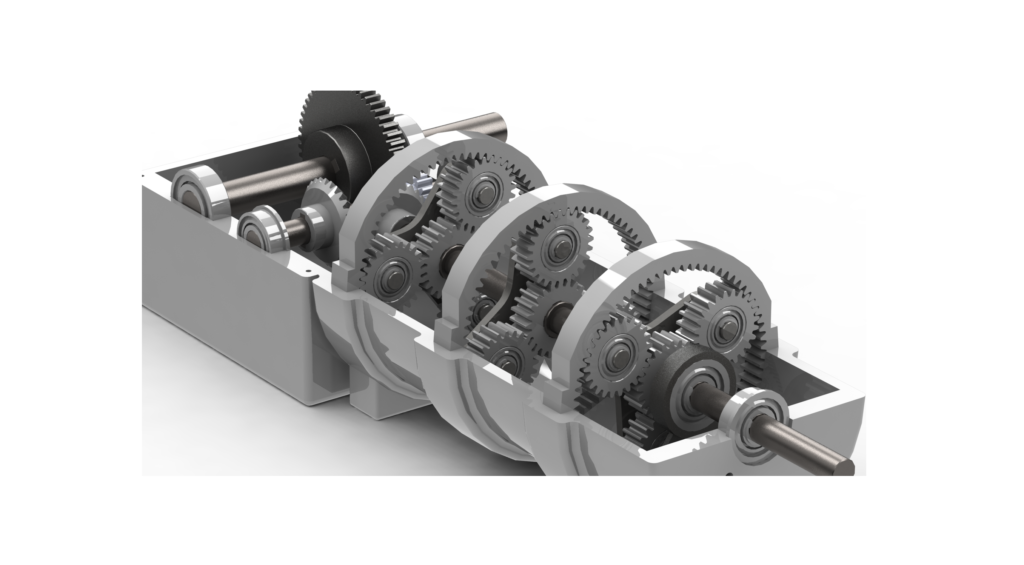

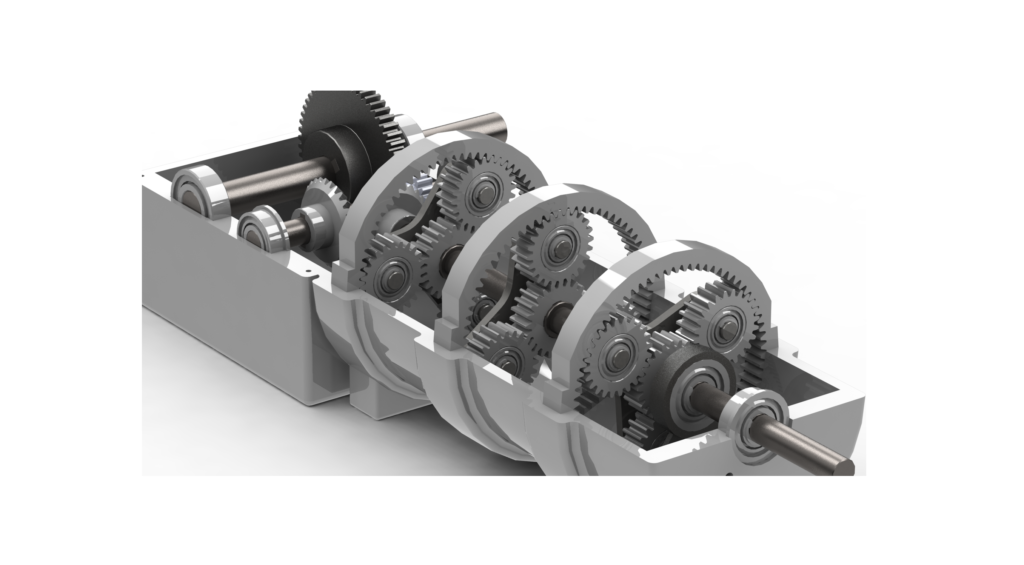

- Combination of Gear Stages:

Planetary gears can be combined into multiple stages, with each stage having its own set of sun gears, planet gears, and ring gears. This arrangement allows for further variations in torque transmission. By connecting the output of one stage to the input of another, the torque can be further amplified or reduced, providing flexibility in power transmission systems.

- Custom Gear Ratios:

By selecting the appropriate sizes and numbers of teeth for the sun gears, planet gears, and ring gears, custom gear ratios can be achieved in planetary gear systems. This allows for precise control over torque transmission and enables the adaptation of the gear arrangement to specific application requirements.

In summary, planetary gears handle variations in direction and torque transmission through their ability to reverse direction without additional components, torque amplification or reduction based on gear arrangement, combination of multiple gear stages, and the ability to achieve custom gear ratios. These features make planetary gears a versatile choice for a wide range of applications requiring efficient and flexible power transmission.

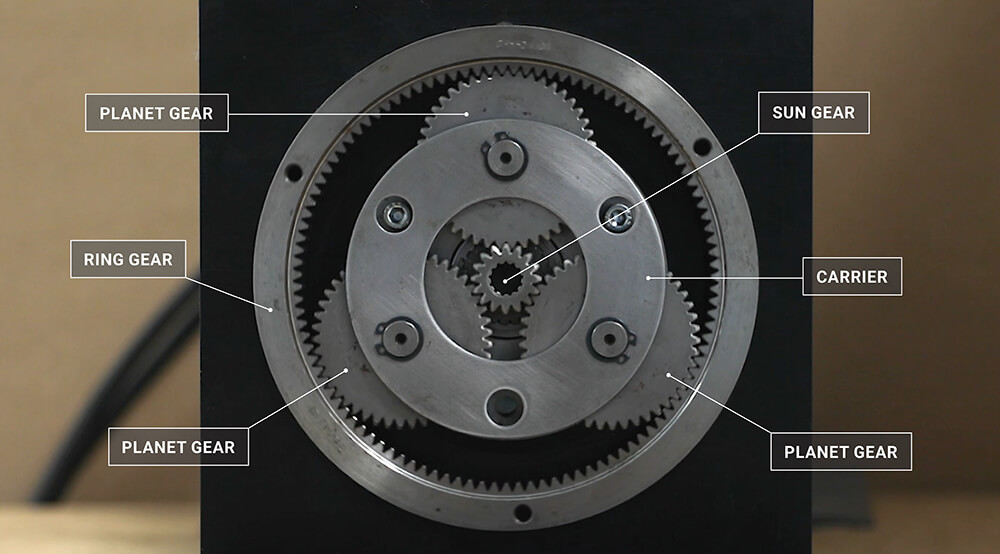

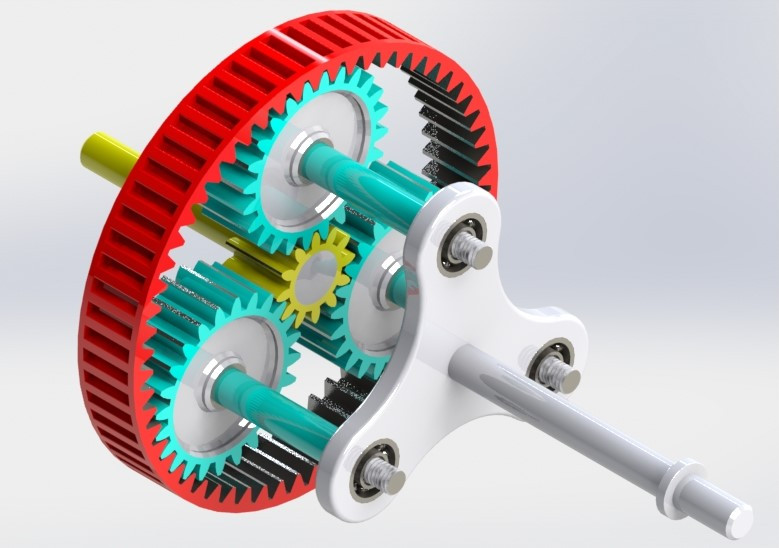

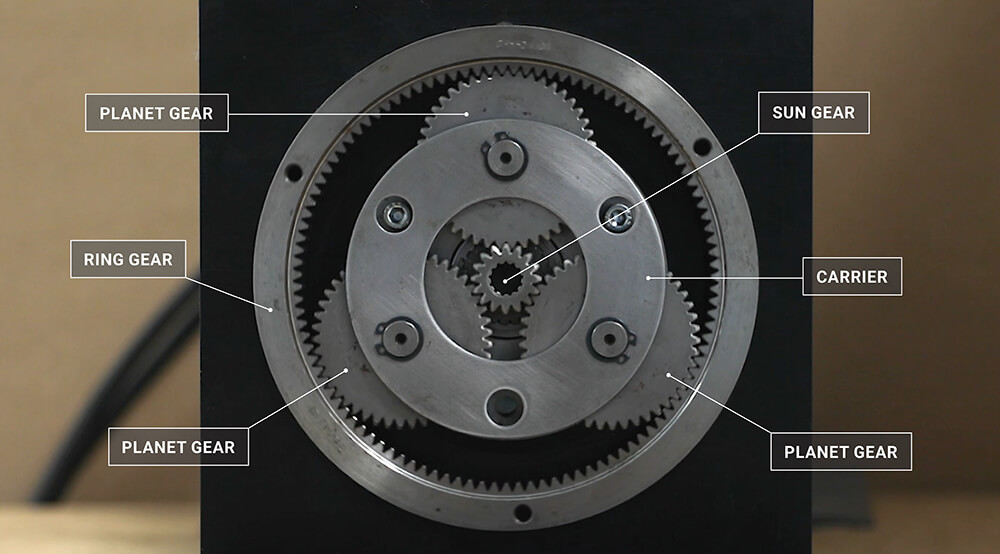

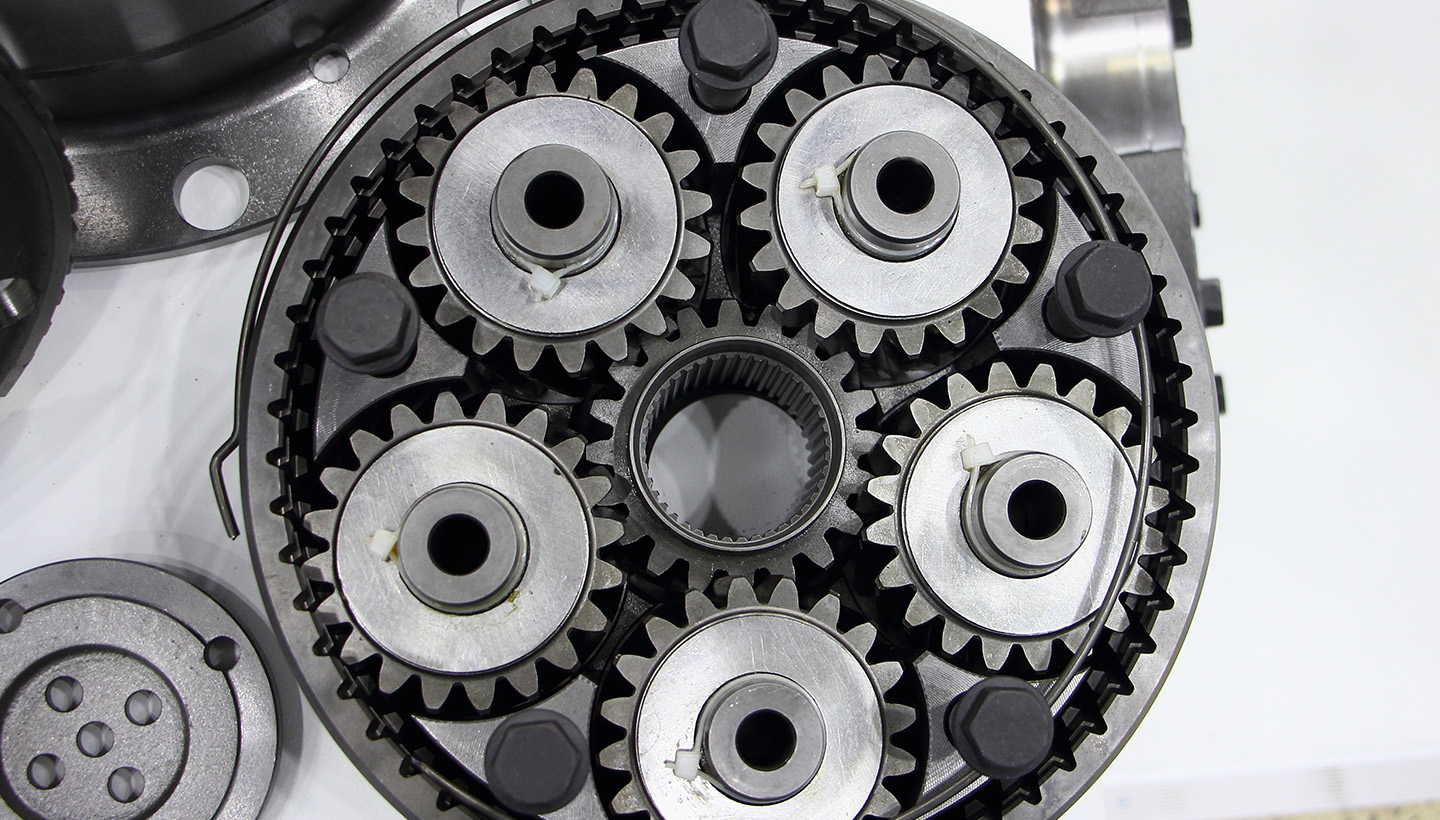

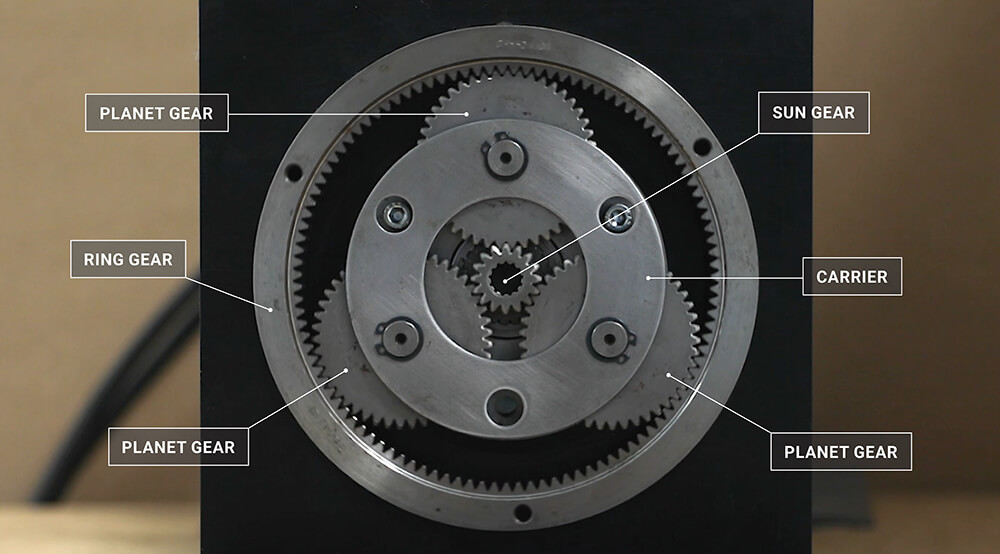

Can you describe the role of sun gears, planet gears, and ring gears in planetary systems?

In a planetary gear system, each component—the sun gear, planet gears, and ring gear—plays a crucial role in the overall operation and functionality. Let’s explore the roles of these gears:

- Sun Gear:

The sun gear is a central component in a planetary gear system. It is typically located at the center and is driven by an input source such as a motor or engine. The sun gear receives the input power and transmits it to the other gears in the system. As the sun gear rotates, it drives the rotation of the planet gears, which, in turn, contribute to the overall gear operation. The size and number of teeth on the sun gear determine the gear ratio and torque characteristics of the system.

- Planet Gears:

The planet gears are gears that surround the sun gear in a planetary gear system. They are typically smaller in size compared to the sun gear and are connected to a carrier or arm. The planet gears mesh with both the sun gear and the ring gear. As the sun gear rotates, it drives the rotation of the planet gears. The planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement allows the planet gears to transmit torque and contribute to the overall gear reduction or amplification. The arrangement and number of planet gears can vary depending on the specific design and requirements of the system.

- Ring Gear:

The ring gear is the outermost gear in a planetary gear system. It has internal teeth that mesh with the planet gears. The ring gear remains fixed or stationary while the sun gear and planet gears rotate. The interaction between the planet gears and the ring gear enables the gear system to achieve gear reduction or amplification. The size and number of teeth on the ring gear also influence the gear ratio and torque characteristics of the system.

In summary, the sun gear serves as the primary driver, receiving the input power and transmitting it to the other gears. The planet gears rotate and orbit around the sun gear, contributing to torque transmission and gear functionality. The ring gear remains fixed and meshes with the planet gears, allowing for gear reduction or amplification. Together, these gears work in harmony to achieve the desired gear ratios, torque transmission, and overall operation of planetary gear systems.

editor by CX 2023-11-01

China supplier ZD 42mm Brush/Brushless Precision Planetary Transmission Gear Motor Rolling Gear gear cycle

Product Description

ZD 42mm Brush/Brushless Precision Planetary Transmission Gear Motor Rolling Gear

Detailed Photos

Product Parameters

MODEL:Z42DPN2425-30S(42ZPN33.92K)

Other Related Products

Click Here For More Details

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you !

| Application: | Motor, Electric Cars |

|---|---|

| Function: | Change Drive Torque, Speed Changing |

| Layout: | Transmission |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

What are the advantages of using planetary gears in various mechanical setups?

Planetary gears offer several advantages that make them a popular choice in various mechanical setups. Let’s explore some of these advantages:

- Compact Size:

One key advantage of planetary gears is their compact size. The arrangement of multiple gears within a single housing allows for a high gear reduction ratio in a relatively small space. This compactness is particularly beneficial in applications where space is limited, such as automotive transmissions, robotics, and aerospace systems.

- High Torque Density:

Planetary gears provide high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This makes them suitable for applications requiring high torque transmission, such as heavy machinery, industrial equipment, and automotive drivetrains.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The multiple gear engagements and the distribution of load among the gears result in reduced friction and minimal power loss. This efficient power transmission ensures that a substantial portion of the input power is effectively transmitted to the output, leading to improved overall system efficiency.

- Multiple Gear Ratios:

Another advantage of planetary gears is their ability to achieve multiple gear ratios within a single gear system. By varying the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. This flexibility allows for adapting to various speed and torque requirements without the need for additional gear sets or complex mechanisms.

- Shock Absorption:

Planetary gears have a natural ability to absorb shock loads and distribute them across multiple gear teeth. The multiple gear engagements and the design characteristics of planetary gears help mitigate shocks and impacts, preventing damage to the gear system and the connected components. This makes them suitable for applications that involve sudden changes in load or intermittent operation.

- Precise Motion Control:

Due to their design, planetary gears offer precise motion control. The combination of rotational and orbital movements of the planet gears allows for smooth and accurate motion transmission. This feature is particularly useful in applications requiring precise positioning, such as robotics, automation systems, and medical equipment.

In summary, the advantages of using planetary gears in various mechanical setups include compact size, high torque density, efficient power transmission, multiple gear ratios, shock absorption, and precise motion control. These advantages make planetary gears well-suited for a wide range of applications across industries, offering reliability, efficiency, and versatility.

Can planetary gears be used in robotics and automation?

Planetary gears are commonly used in robotics and automation due to their numerous advantages and suitability for various applications. Let’s explore how planetary gears are utilized in robotics and automation:

- Compact Size and High Power Density:

Planetary gears offer a high power density, meaning they can transmit significant torque in a compact size. This characteristic is particularly valuable in robotics and automation systems, where space is often limited. The compactness of planetary gears allows for efficient integration into robotic joints, gearboxes, and other motion control components.

- Precision and Repeatability:

Planetary gears provide high precision and repeatability, making them suitable for precise positioning and motion control tasks in robotics and automation. The gear design and arrangement contribute to minimal backlash and accurate torque transmission, ensuring precise and predictable movements. This precision is essential in applications such as robotic arms, CNC machines, and pick-and-place systems.

- Speed Reduction and Torque Amplification:

Planetary gears offer the capability of speed reduction and torque amplification, allowing robots to handle varying loads and achieve different levels of speed and force. By utilizing the gear ratios and multiple gear stages, planetary gears enable robots to perform tasks that require both high torque and precise movements, such as lifting heavy objects or performing delicate assembly operations.

- Efficiency and Energy Savings:

Planetary gears are known for their high efficiency in power transmission. The gear design minimizes friction and ensures efficient torque transfer, resulting in reduced energy consumption. In robotics and automation, where energy efficiency is often a concern, the use of planetary gears can contribute to overall energy savings and longer battery life in battery-powered systems.

- Reliability and Durability:

Planetary gears are designed to be robust and durable, capable of withstanding demanding operating conditions. They can handle high loads, provide long service life, and resist wear and fatigue. These characteristics are crucial in robotics and automation, where the gears are subjected to repetitive and continuous motion. The reliability and durability of planetary gears contribute to the overall performance and longevity of robotic systems.

- Versatility and Customization:

Planetary gears offer versatility and customization options to meet specific requirements in robotics and automation. They can be combined with other mechanical components such as motors, encoders, and sensors to create tailored motion control systems. The ability to select different gear ratios, sizes, and configurations allows for the optimization of robotic designs for specific applications and performance criteria.

In summary, planetary gears are widely used in robotics and automation due to their compact size, high power density, precision, repeatability, speed reduction, torque amplification, efficiency, reliability, durability, versatility, and customization options. These qualities make planetary gears an excellent choice for various robotic applications, including industrial automation, collaborative robots, robotic prosthetics, unmanned vehicles, and many others.

What is the purpose of using planetary gears in machinery?

Planetary gears serve several important purposes in machinery and mechanical systems. Let’s delve into the key purposes and benefits of using planetary gears:

- Gear Ratio Variation:

One of the primary purposes of planetary gears is to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. This flexibility enables machinery to adapt to varying speed and torque requirements, allowing for precise control and efficient power transmission.

- Torque Amplification:

Planetary gears are known for their ability to amplify torque. The arrangement of multiple gear sets in a compact design allows for torque multiplication. This can be particularly beneficial in applications where high torque is required while maintaining a smaller form factor. Planetary gears can efficiently transmit torque and handle heavy loads.

- Compact Size:

Another advantage of planetary gears is their compact size. The internal gear meshing and the integration of multiple gear sets within a single gear system contribute to their space-saving design. This compactness is valuable in machinery where space constraints are a consideration, enabling the design of more compact and lightweight systems.

- High Efficiency:

Planetary gears are known for their high efficiency in power transmission. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. This efficiency is crucial in machinery where energy conservation and optimization are important factors.

- Directional Control:

Planetary gears allow for bidirectional power transmission. By controlling the direction of rotation of the input and output elements, the direction of rotation in the machinery can be easily changed. This feature is useful in applications that require reversing the direction of rotation or changing the rotational direction without the need for additional mechanisms.

- Shock Absorption:

The arrangement of multiple gears in a planetary gear system provides inherent shock-absorbing capabilities. The distributed load between the gear teeth helps to dampen vibrations and absorb shocks, contributing to smoother operation and reduced wear on the system components.

- Application Versatility:

Planetary gears find applications in a wide range of machinery and mechanical systems. They are commonly used in automotive transmissions, industrial machinery, robotics, aerospace systems, power generation equipment, and more. The versatility of planetary gears stems from their ability to provide precise control, compactness, high torque transmission, and efficient power transmission.

In summary, the purpose of using planetary gears in machinery is to achieve variable gear ratios, amplify torque, maintain compact size, ensure high efficiency in power transmission, enable bidirectional control, absorb shocks, and provide versatility for various applications. The unique characteristics of planetary gears make them valuable components in diverse machinery and mechanical systems.

editor by CX 2023-11-01

China Hot selling Processing Small Modulus Steel Tooth Metal Internal External Gear Set Reducer Planetary Gear worm gear winch

Product Description

Product Paramenter

| Products | gears |

| Module | M0.5-M10 |

| Precision grade | DIN6, DIN7, DIN8, DIN10 |

| Pressure angle | 20 degree |

| Material | Aluminum,Brass,SS C45 steel, Stainless steel 304, Plastic, Brass, 20CrMo,40Cr and so on |

| Heat treatment | Hardening and Tempering, High Frequency Quenching,Carburizing etc |

| Surface treatment | Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems.Automated warehousing systems. |

| Machining process | Hobbing, Milling, Drilling, Shaving, Grinding |

Product Display

Descriptions:

1.According to the different strength and performance, we choose the steel with

strong compression;

2.Using Germany professional software and our professional engineers to design

products with more reasonable size and better performance;

3.We can customize our products according to the needs of our customers,Therefore,

the optimal performance of the gear can be exerted under different working conditions;

4.Quality assurance in every step to ensure product quality is controllable.

Our Factory

Specializing in the production of “engineering plastic accessories” of high-tech enterprises,

the company has a set of imported production equipment and CNC processing equipment,

processing means advanced, strong technical force.

Certificate

Companies strictly enforce the ISO9001(2008)international quality certification system, the product

quality conforms to the eu RoHS standard.

Our Factory

| Material: | Metal |

|---|---|

| Size: | According to Drawing or Sample |

| Color: | Customized |

| Tooling: | CNC Lathe |

| Warranty: | Yes |

| Free Sample: | Yes |

| Customization: |

Available

| Customized Request |

|---|

How does a planetary gear arrangement handle variations in load and stress?

A planetary gear arrangement offers inherent advantages in handling variations in load and stress. Let’s explore how it achieves this:

- Distributed Load:

One of the key advantages of a planetary gear arrangement is its ability to distribute the load among multiple gears. In this arrangement, the load is shared by the sun gear, planet gears, and ring gear, with each gear sharing a portion of the total load. As a result, the load on each individual gear is reduced compared to a single gear system, reducing stress concentration and enhancing the overall load-carrying capacity.

- Load Sharing:

Planet gears in a planetary gear system share the load as they are meshed with both the sun gear and the ring gear. This load-sharing characteristic ensures that the load is distributed evenly across multiple gear teeth and contact points. Consequently, the stress on each gear is reduced, minimizing the risk of tooth failure and increasing the system’s durability.

- Torque Splitting:

In a planetary gear arrangement, torque can be split among multiple paths. By controlling the distribution of torque between the sun gear and ring gear, variations in load can be managed effectively. If one gear path experiences higher stress, the torque distribution can be adjusted to shift the load to other gear paths, thereby balancing the stress and minimizing the risk of gear failure.

- Multiple Stages:

Planetary gear arrangements can be designed with multiple stages, involving multiple sets of sun gears, planet gears, and ring gears. Each stage can handle a portion of the load, allowing for further load distribution and stress reduction. This multi-stage configuration enhances the gear arrangement’s capacity to handle variations in load and stress, making it suitable for demanding applications.

- Robust Construction:

Planetary gear systems are known for their robust construction and high torque capacity. They are designed to withstand heavy loads and resist the effects of stress concentration. The use of high-quality materials and precise manufacturing techniques further enhances their ability to handle variations in load and stress.

In summary, a planetary gear arrangement handles variations in load and stress through distributed load sharing, torque splitting, multiple stages, and robust construction. By distributing the load among multiple gears, sharing the load between different paths, and employing multiple gear stages, a planetary gear arrangement can effectively manage variations in load and stress, ensuring reliable and durable operation in a wide range of applications.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

What industries commonly use planetary gears in their applications?

Planetary gears find applications in a wide range of industries and mechanical systems. Let’s explore some of the industries that commonly utilize planetary gears:

- Automotive Industry:

The automotive industry extensively uses planetary gears in various applications. Planetary gears are commonly found in automatic transmissions, where they enable smooth gear shifting, provide different gear ratios, and transmit torque efficiently. They are also used in differential systems, allowing wheels to rotate at different speeds while maintaining power distribution.

- Robotics and Automation:

Planetary gears play a crucial role in robotics and automation systems. They are employed in robotic joints and actuators to provide precise motion control, compact size, and high torque transmission. Planetary gears enable robotic arms to move accurately and handle heavy loads, making them essential components in industrial robots and robotic manipulators.

- Aerospace and Aviation:

The aerospace and aviation industries utilize planetary gears in various applications. They are used in aircraft landing gear systems, where they provide reliable torque transmission and compact design. Planetary gears are also employed in aircraft engine systems, helicopter rotor systems, and satellite mechanisms due to their efficiency, high torque capacity, and ability to operate in space-restricted environments.

- Power Generation:

Planetary gears are utilized in power generation equipment, including wind turbines and hydroelectric generators. In wind turbines, planetary gears enable the conversion of low-speed rotor rotation to high-speed generator rotation, ensuring efficient power generation. They are also employed in hydroelectric generators to transmit power from turbines to electrical generators, providing gear reduction and torque amplification.

- Industrial Machinery:

Planetary gears are widely used in industrial machinery applications. They are found in heavy-duty machinery such as mining equipment, construction machinery, and material handling systems. Planetary gears provide high torque transmission, compactness, and durability, making them suitable for handling demanding tasks in industrial environments.

- Marine and Shipbuilding:

The marine and shipbuilding industries employ planetary gears in various marine propulsion systems. They are used in marine engines, propeller systems, and thrusters. Planetary gears provide efficient power transmission, speed control, and compact design for propulsion systems in vessels ranging from small boats to large ships.

- Medical Equipment:

In the medical field, planetary gears are utilized in various equipment and devices. They are found in medical imaging systems like CT scanners and MRI machines, providing precise motion control and reducing image distortion. Planetary gears are also used in surgical robots and medical devices that require compact size, high torque, and accurate positioning.

These are just a few examples of the industries that commonly use planetary gears in their applications. The versatility, efficiency, and compactness of planetary gears make them suitable for a broad range of industries where precise motion control, torque transmission, and space-saving design are essential requirements.

editor by CX 2023-11-01

China supplier CZPT Truck 5801275973 Planetary Gear manufacturer

Product Description

Product Description

SAIC Xihu (West Lake) Dis.n truck Planetary gear

| Part name | Planetary gear |

| part number | 5801275973 |

|

Packing |

standard packing |

| Shipping | By Air/Sea /train/Truck/Express |

| MOQ | 4ps |

| Advantage | fast delivery and good quality |

Detailed Photos

Certifications

Company Profile

Our Advantages

1. We have more than 10 years experience in diesel injection pump spare parts, SAIC Xihu (West Lake) Dis.n truck spare parts and gasoline generator. Especially for diesel injection pump spare parts we can supply more than thousand type.

2. We cooperate with many certificated OEM factories of diesel injection pump spare parts who have advanced equipment and technology.

3. We provide a full range of SAIC Xihu (West Lake) Dis.n truck parts, such as Genlyon, Kingkan truck parts.We also have full stock for general parts so we can deliver in a short time.

4. High Quality + Reasonable Price + Quick Response + Technical Support, is what we are trying to offer you the best cooperation experience.

5. We are the first class distributor of CHINAMFG and SAIC Xihu (West Lake) Dis.n, good price and genuine quality is available.

FAQ

1: How to contact you?

A: You can send inquiry to us directly or you can contact us by email,phone call or WhatsApp, WeChat, Facebook and Skype. We will try to reply you as soon as possible.

Q2:Do you provide sample?

A:Yes, we accept sample order, you can buy 1-6pcs as sample to test our parts quality (sample charges and courier cost by your side) , we have confidence in our quality.

Q3: What packing do you have?

A: We have 3 type neutral packing, and we also accept customized packing.

Q4: What is the delivery time?

A: within 3-5 working days for the parts in stock, for out of stock parts, please confirm with us, we will check the production time according to your quantity

Q5: What is the shipping way?

A:We can send by air,by land,by sea or by express(courier) like DHL,UPS,TNT,FedEx,Aramax according to your request.

Q6:How can I make payment if the order is confirmed?

A:We accept Western Union,Bank Transfer(In USD or in RMB), Alipay, WeChat Pay. You can choose as you like.

Q7: What is your warranty ?

A:We usually provide 3 months’ after-sales service for non-artificial damage.

| Warranty: | 3 Months |

|---|---|

| Certification: | ISO9001 |

| Color: | Silver |

| Part Name: | Planetary Gear |

| Part Number: | 5801275973 |

| Dlivery Time: | 5 Working Days |

| Customization: |

Available

| Customized Request |

|---|

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

Can you explain the process of gear shifting in planetary gear systems?

Gear shifting in planetary gear systems involves changing the gear ratio by engaging or disengaging specific components of the gear set. Let’s explore the process of gear shifting in more detail:

- Clutching and Braking:

The gear shifting process in planetary gear systems primarily relies on clutching and braking mechanisms. These mechanisms selectively connect or disconnect various gears within the system to achieve the desired gear ratio. Here are the key steps involved:

- Clutch Engagement:

To shift to a higher gear ratio, the clutch associated with the gear component that needs to be engaged is activated. The clutch connects the rotating member, such as the sun gear, planet carrier, or ring gear, to the stationary member, allowing torque transmission. This engagement results in a change in the gear ratio, leading to higher speed or torque output depending on the specific gear set configuration.

- Brake Application:

On the other hand, to shift to a lower gear ratio, a brake associated with the gear component that needs to be disengaged is applied. The brake immobilizes or slows down the rotation of the selected gear element, preventing it from transmitting torque. By selectively braking certain components, the gear ratio is altered, resulting in a lower speed or higher torque output.

- Sequential Shifting:

In some planetary gear systems, gear shifting is performed sequentially. This means that one gear component is engaged or disengaged at a time, gradually transitioning from one gear ratio to another. Sequential shifting allows for smooth and controlled gear changes, minimizing the stress on the transmission components and ensuring seamless power transmission.

- Electronic Control:

In modern applications, gear shifting in planetary gear systems is often electronically controlled. Electronic control systems utilize sensors, actuators, and a control unit to monitor various parameters such as vehicle speed, engine load, and driver input. Based on these inputs, the control unit determines the optimal gear shift points and actuates the clutches and brakes accordingly. Electronic control enhances the efficiency, precision, and automation of the gear shifting process.

In summary, gear shifting in planetary gear systems involves the engagement and disengagement of clutches and brakes to alter the gear ratio. By selectively connecting or disconnecting specific gear components, the speed and torque output can be adjusted. Sequential shifting and electronic control systems further enhance the gear shifting process, providing smooth and efficient operation in various applications, including automotive transmissions and industrial machinery.

Can you describe the role of sun gears, planet gears, and ring gears in planetary systems?

In a planetary gear system, each component—the sun gear, planet gears, and ring gear—plays a crucial role in the overall operation and functionality. Let’s explore the roles of these gears:

- Sun Gear:

The sun gear is a central component in a planetary gear system. It is typically located at the center and is driven by an input source such as a motor or engine. The sun gear receives the input power and transmits it to the other gears in the system. As the sun gear rotates, it drives the rotation of the planet gears, which, in turn, contribute to the overall gear operation. The size and number of teeth on the sun gear determine the gear ratio and torque characteristics of the system.

- Planet Gears:

The planet gears are gears that surround the sun gear in a planetary gear system. They are typically smaller in size compared to the sun gear and are connected to a carrier or arm. The planet gears mesh with both the sun gear and the ring gear. As the sun gear rotates, it drives the rotation of the planet gears. The planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement allows the planet gears to transmit torque and contribute to the overall gear reduction or amplification. The arrangement and number of planet gears can vary depending on the specific design and requirements of the system.

- Ring Gear:

The ring gear is the outermost gear in a planetary gear system. It has internal teeth that mesh with the planet gears. The ring gear remains fixed or stationary while the sun gear and planet gears rotate. The interaction between the planet gears and the ring gear enables the gear system to achieve gear reduction or amplification. The size and number of teeth on the ring gear also influence the gear ratio and torque characteristics of the system.

In summary, the sun gear serves as the primary driver, receiving the input power and transmitting it to the other gears. The planet gears rotate and orbit around the sun gear, contributing to torque transmission and gear functionality. The ring gear remains fixed and meshes with the planet gears, allowing for gear reduction or amplification. Together, these gears work in harmony to achieve the desired gear ratios, torque transmission, and overall operation of planetary gear systems.

editor by CX 2023-11-01

China Good quality CZPTPart Diff. Planetary Gear Wg9012320010 bevel spiral gear

Product Description

SINOTRUCK CHINAMFG PART DIFF.PLANETARY GEAR (19901232571)

| Company | ChinaMach Industry Co.,Ltd |

| Brand | SINOTRUK HOWO/WEICHAI/MAN/SHACMAN/FAW/FOTON/AUMAN/NORTHBENZ/SAN Y/SHXIHU (WEST LAKE) DIS.I/SDLG |

| QUALITY | Original part/OE part |

| Payment term | T/T L/C , Flexible billing method |

| Packing | Standard packing |

We can provide:

TRUCK

Sales Chinese trucks and construction machinery,Provide modificationsu,pgrades, consulting services

SPARE TRUCK

Supply China Truck spare parts and construction machinery parts. Products Include: Sinotruk HOWO, CHINAMFG Power , Fonton, Shacman, SHXIHU (WEST LAKE) DIS.I, SAN Y ,SDLG

SERVICE

Provide cargo warehousing, packaging, shipping and export agency services

Agent procurement, inspection The inspection agency

| Certification: | ISO9001 |

|---|---|

| Driving System Parts: | Frame |

| Electrical System Parts: | Starting System |

| Brake System Parts: | Brake |

| Transmission System Parts: | Transmission Shaft |

| Steering System Parts: | Steering Transmission Device |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

How do planetary gears handle variations in tooth engagement during operation?

Planetary gears are designed to handle variations in tooth engagement during operation, ensuring smooth and reliable performance. Let’s explore how planetary gears address these variations:

- Tolerance for Misalignment:

Planetary gears are designed with a certain degree of tolerance for misalignment. This means that slight variations in tooth engagement due to manufacturing tolerances, assembly, or operating conditions are accommodated without causing significant impact on the gear system. The gear teeth are carefully designed with appropriate profiles, clearances, and backlash to allow for some degree of misalignment while maintaining proper functioning.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load across multiple gear teeth. Each planet gear shares the load with the adjacent gears, reducing the stress on individual teeth and promoting even tooth engagement. This load distribution capability helps minimize localized wear, noise, and vibration, resulting in smoother and more efficient operation.

- Flexible Mounting and Support:

Planetary gears are often mounted on flexible support structures, such as bearings or flexible couplings. These components help absorb and compensate for small variations in tooth engagement during operation. The flexible mounting and support systems provide some degree of flexibility and compliance, allowing the gears to self-adjust and maintain proper tooth contact under varying operating conditions.

- Lubrication and Cooling:

Proper lubrication and cooling play a crucial role in handling variations in tooth engagement. Lubricants reduce friction and wear between gear teeth, ensuring smooth operation and minimizing the impact of tooth engagement variations. Additionally, effective cooling mechanisms help dissipate heat generated during operation, preventing excessive temperature rise that could affect the gear meshing performance.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques. This robust construction enhances the gear system’s ability to withstand variations in tooth engagement. By ensuring high-quality gear components, proper heat treatment, and stringent quality control, planetary gears are built to handle the dynamic loads and variations encountered during operation.

In summary, planetary gears handle variations in tooth engagement through their tolerance for misalignment, load distribution among multiple planet gears, flexible mounting and support, effective lubrication and cooling, and robust construction. These design considerations and features enable planetary gears to maintain proper tooth contact, minimize wear and noise, and ensure reliable performance in various applications, including automotive transmissions, industrial machinery, and power transmission systems.

How do planetary gears differ from other types of gear arrangements?

Planetary gears, also known as epicyclic gears, possess unique characteristics and differ from other types of gear arrangements in several ways. Let’s explore the distinguishing features of planetary gears:

- Internal Gear Meshing:

Unlike other gear arrangements where the gears typically mesh externally, planetary gears have internal gear meshing. This means that the gear teeth of the sun gear, planet gears, and ring gear are located on the inside surfaces, allowing for compact and space-efficient designs.

- Multiple Gear Sets:

Planetary gear systems consist of multiple gear sets working in parallel or series. These gear sets include the sun gear, planet gears, and ring gear. By combining and configuring these gear sets, different gear ratios and torque distributions can be achieved, providing versatility and flexibility in various applications.

- Central Sun Gear:

A distinctive feature of planetary gears is the presence of a central sun gear. The sun gear is typically driven by an input source, such as a motor or engine. It is located at the center of the gear arrangement and serves as the primary driver for overall gear operation.

- Orbiting Planet Gears:

In planetary gears, the planet gears rotate on their own axes while simultaneously orbiting around the sun gear. This combination of rotational and orbital movement allows for efficient torque transmission and enables the gear arrangement to achieve different gear ratios based on the relative sizes and positions of the gears.

- Compact Size:

One of the key advantages of planetary gears is their compact size. The internal gear meshing and the arrangement of multiple gear sets within a single gear system contribute to their space-saving design. This makes planetary gears suitable for applications where size and weight restrictions are important considerations.

- Wide Range of Applications:

Planetary gears find applications in various industries and mechanical systems. They are commonly used in automotive transmissions, industrial machinery, robotics, aerospace systems, and more. Their ability to achieve different gear ratios, transmit torque efficiently, and operate in compact spaces makes them versatile solutions in diverse engineering applications.

In summary, planetary gears differ from other types of gear arrangements due to their internal gear meshing, multiple gear sets, central sun gear, orbiting planet gears, compact size, and wide range of applications. These characteristics make planetary gears suitable for achieving various gear ratios, transmitting torque efficiently, and meeting the space requirements of different mechanical systems.

editor by CX 2023-11-01

China high quality Factory Inter-Axle Differential Planetary Planet Gear for CZPT Ud Truck Parts CF0401m0-9 with Best Sales

Product Description

Factory Directly Sales Inter-axle Differential Planetary Planet Gear For Ford Truck Spare Parts CF0401M0-9

Detailed Photos

Product advantages & features

(1) Accessory products of the truck, use 20CrMmti material.

(2) Heat treatment and tempering, high gear root strength, stronger impact resistance.

(3) Multi-purpose CHINAMFG carburizing processing, fine grinding processing technology, effectively reducing noise.

(4) Test product 1 by one, and inspect each product on delivery to ensure 100% quality stability of the product.

(5) The unified brand carton, inner bag and integral foam packaging, which is strong and beautiful.

Factory Show

More Products

Middle Axle Series

| NO. | Consumption | Parts Number |

| 1 | 20 | Q1801220TF2 |

| 2 | 2 | JL0041M0-2 |

| 2 | 2 | JL0040M0-1 |

| 3 | 2 | Q341C12T13F2 |

| 4 | 2 | EG0040B0-0 |

| 5 | 4 | GF0002B0-9 |

| 1 | BB0040A0-1 | |

| 6 | 2 | BB0040M0-3 |

| 7 | 2 | Q43060 |

| 8 | 2 | AF0040S0-2 |

| 9 | 4 | FM0042B0-9 |

| 10 | 10 | DK0042B0-5 |

| 11 | 20 | GC0042B0-0 |

| 12 | 10 | CH0040M0-0 |

| 12 | 440 | FA0041B0-6 |

| 12 | 10 | EZ0073B0-5 |

| 13 | 10 | DQ0041M0-1 |

| 14 | 20 | GC0043B0-1 |

| 15 | 10 | Q43129 |

| 16 | 2 | DN0040M0-7 |

| 17 | 2 | DJ0003B0-1 |

| 18 | 2 | FM0002B0-5 |

| 19 | 2 | EB0001B0-2 |

| 20 | 2 | DJ0002B0-0 |

| 21, 22, 23 | 2 | CJ0040A0-0 |

| 21 | 2 | CJ0040M0-2 |

| 22 | 2 | FC0040M0-8 |

| 23 | 2 | 2SFN0054B0-3 |

| 24 | 4 | Q218B1225TF2 |

| 25 | 2 | BU0051M0-4 |

| 25 | 4 | Q2541040 |

| 26 | 1 | EN0063M0-3 |

| 1 | EN0064M0-4 | |

| 27 | 2 | FK0043A0-7 |

| 28 | 2 | EJ0044B0-7 |

| 29 | 2 | CU0049M0-2 |

| 29 | 2 | CU0048M0-1 |

| 29 | 2 | Q5211571 |

| 30 | 20 | FG0052B0-4 |

| 30 | 20 | FG0050B0-2 |

| 31 | 20 | DJ0057B0-0 |

| 32 | 2 | FK0044A0-8 |

| 33 | 2 | EH0002B0-9-B |

| 35 | 4 | D12-5711 |

| 36 | 4 | DQ0040B0-9 |

| 37 | 2 | D13-5711 |

| 38 | 4 | D23-5711 |

| 39 | 4 | MZ0040B0-7 |

| 39 | 4 | D22-5711 |

| 40 | 4 | ET0075A1-1 |

| 41 | 28 | AJ0007B0-2 |

| 42 | 28 | DJ0004B0-2 |

| 42 | 28 | FM0003B0-6 |

| 43 | 2 | GE0001M0-8 |

| 43 | 2 | GE0001M0-9 |

| 43 | 2 | C25-5711 |

| 43 | 2 | C18-5712 |

| 44 | 2 | BH0048S0-3 |

| 2 | BH0049S0-4 | |

| 44 | 2 | 2SBH0040S0-5 |

| 2 | 2SBH0041S0-6 | |

| 44 | 8 | DW0040B0-5 |

| 45 | 12 | H19-5711 |

| 46 | 12 | H20-5711 |

| 47 | 4 | C14-0301 |

| 48 | 2 | AP0049B0-4 |

| 48 | 4 | AP0050B0-6 |

| 49 | 2 | C15-0111 |

| 50 | 1 | AT0054M0-5 |

| 1 | AT0055M0-6 | |

| 51 | 2 | Q151B1635TF2 |

| 52 | 2 | Q151B1685TF2 |

| 53 | 2 | AM0066M0-1 |

| 53 | On demand | ES0073B0-8 |

| ES0074B0-9 | ||

| 53 | 2 | AP0049B0-4 |

| 53 | 4 | C14-0301 |

| 53 | 2 | C17-5711 |

| 54 | 2 | C18-5712 |

| 57 | 1 | AB0043A0-3 |

| 1 | AB0044A0-4 | |

| 1 | AB0050A0-1 | |

| 1 | AB0051A0-2 | |

| 58 | On demand | C15-5715 |

| 59 | 2 | C16-0301 |

| 60 | 1 | CP0049A0-5 |

| 61 | 1 | AL0042M0-4 |

| 1 | BT0040B0-0 | |

| 62 | 6 | Q151B1845TF2 |

| 63 | 1 | GF0002B0-9 |

| 64 | 1 | AN0096M0-5 |

| 1 | AN0097M0-6 | |

| 65 | 1 | AN0094M0-3 |

| 1 | AN0095M0-4 | |

| 4 | BT0041B0-1 | |

| 66 | 8 | Q151B22240TF2 |

| 67 | 1 | GG0002B0-0 |

| 68 | 1 | Q618B06 |

| 69 | GJ0001B0-2 | |

| 70 | 1 | BD0049B0-3 |

| 1 | BD0050B0-5 | |

| 71 | 2 | AP0042B0-2 |

| 72 | 2 | GM0040B0-8 |

| 73 | 16 | AJ0002B0-7 |

| 74 | 1 | AX0074A0-9 |

| 1 | AX0075A0-0 | |

| 75 | 1 | 2SDJ0047B0-9 |

| 76 | 1 | 2SBY0051M0-8 |

| 77 | 4 | Q151B1455TF2 |

| 4 | 2SDJ0051B0-4 | |

| 78 | 1 | EH0042B0-3 |

| 79 | 1 | 2SEB0044M0-0 |

| 80 | On demand | 2SES0069B0-3 |

| 81 | 2 | FL0046A0-1 |

| 82 | 4 | Q150B1571 |

| 83 | 4 | Q4571 |

| 84 | 1 | 2SAR0040M0-8 |

| 85 | 1 | 2SBN0040A0-3 |

| 86 | 1 | EP0044M0-4 |

| 78–86 | 1 | AR0042A0-8 |

| NO. | Consumption | Parts Number |

| 1 | AX0074A0-9 | |

| 1 | AX0075A0-0 | |

| 1 | 1 | 3SDJ0001B0-9 |

| 2 | 1 | 2SBY0049M0-5 |

| 1 | 2SER0043S0-1 | |

| 3 | 1 | EH0043B0-4 |

| 4 | 12 | AJ0042B0-1 |

| 5 | 1 | AR0042M0-0 |

| 1 | DK0043B0-6 | |

| 6 | ES0052B0-5 | |

| 6 | ES0053B0-6 | |

| 6 | ES0054B0-7 | |

| 6 | ES0055B0-8 | |

| 7 | 1 | FK0041A0-5 |

| 8 | 1 | BF0044M0-1 |

| 9 | 1 | 2SEP0043M0-3 |

| 10 | 1 | FA0043B0-8 |

| 11 | 1 | FA0044B0-9 |

| 12 | 1 | FA0044B0-9 |

| 13 | 1 | CD0043M0-9C |

| 14 | 8 | Q150B1050TF2 |

| 8 | Q4571 | |

| 1 | AY0052A0-6B | |

| 15,19 | 1 | AZ0042A1-7 |

| 16 | 1 | FB0040M0-7 |

| 17 | 4 | 2SCF0040M0-8 |

| 4 | 2SCF0040M0-8C | |

| 4 | AP0048B0-3 | |

| 4 | GD0042B0-1 | |

| 18 | 4 | GD0040B0-9 |

| 20,21 | 1 | CE0041A0-6 |

| 20 | 1 | AP0044B0-9B |

| 21 | 2SCE0041M0-8C | |

| 22 | 1 | FK0050A0-5 |

| 22 | 1 | BN0041A0-4 |

| 23,50 | 1 | BA0049A0-9 |

| 24 | 3 | Q180571 |

| 25 | 1 | BN0040B0-4 |

| 1 | DD0041B0-7 | |

| 1 | FR0041B0-3 | |

| 26 | 1 | 2SAU0046M0-7 |

| 1 | EJ0046B0-9 | |

| 27 | 1 | DQ0047M0-7 |

| 28 | 1 | 2SEJ0045B0-8 |

| 29 | 1 | BF0047M0-4 |

| 1 | BF0048M0-5 | |

| 30 | 1 | FE0041B0-0 |

| 31 | 1 | BN0040B0-4 |

| 1 | DD0041B0-7 | |

| 1 | FR0040B0-2 | |

| 32 | 1 | 2SAU0046M0-7 |

| 1 | EJ0046B0-9 | |

| 33 | 3 | Q180571 |

| 34 | 1 | 2SDQ0040M0-0 |

| 35 | 1 | 2SEJ0045B0-8 |

| 36 | 1 | BF0054M0-2 |

| 37 | 1 | FE0044B0-3 |

| 37 | 1 | FE0041B0-0 |

| 37 | 1 | Q150B1230TF2 |

| 1 | Q350B12T15F2 | |

| 38 | 6 | Q1810820TF2 |

| 40 | 1 | BG0042S0-6 |

| 41 | 1 | 3SDJ0001B0-9 |

| 42 | 1 | FK0040A0-4 |

| 43 | 1 | 2SEZ0077B0-9 |

| 1 | 2SEZ0075B0-7 | |

| 44 | 1 | CD0044M0-0 |

| 45 | 1 | FK0042A0-6 |

| 46 | 1 | EZ0074B0-6 |

| 47 | On demand | ES0061B0-5 |

| 47 | On demand | ES0056B0-9 |

| 48, 52 | 1 | CC0066A0-1 |

| 1 | CC0063A0-8 | |

| 49 | 4 | AJ0046B0-5 |

| AY0056A0-0 | ||

| AY0058A0-2 | ||

| AY0066A0-1 | ||

| AY0068A0-3 | ||

| 51, 61 | 1 | 2SAY0048A1-1 |

| 53 | 1 | FK0047A0-1 |

| 54 | 1 | EB0042M0-8 |

| 55 | 1 | BF0046M0-3 |

| 1 | GC0045B0-3 | |

| 1 | Q43170 | |

| 56 | 16 | AJ0004B0-9 |

| 57 | 2 | GC0044B0-2 |

| 57 | 2 | CE0042M0-9 |

| 58 | 4 | GD0041B0-0 |

| 59 | 4 | CF0041M0-9 |

| 60 | 1 | FB0041M0-8 |

| 62 | 16 | Q150B1285TF2 |

| 63 | 1 | FK0048A0-2 |

| 64 | 1 | EB0043M0-9 |

| 65 | 4 | Q150B0820 |

| 4 | Q40308 | |

| 2 | DC0040S0-2 |

Rear Axle Series

| NO. | Consumption | Parts Number |

| 1 | 20 | Q1801220TF2 |

| 2 | 2 | JL0041M0-2 |

| 2 | 2 | JL0040M0-1 |

| 3 | 2 | Q341C12T13F2 |

| 4 | 2 | EG0040B0-0 |

| 5 | 4 | GF0002B0-9 |

| 1 | BB0040A0-1 | |

| 6 | 2 | BB0040M0-3 |

| 7 | 2 | Q43060 |

| 8 | 2 | AF0040S0-2 |

| 9 | 4 | FM0042B0-9 |

| 10 | 10 | DK0042B0-5 |

| 11 | 20 | GC0042B0-0 |

| 12 | 10 | CH0040M0-0 |

| 12 | 440 | FA0041B0-6 |

| 12 | 10 | EZ0073B0-5 |

| 13 | 10 | DQ0041M0-1 |

| 14 | 20 | GC0043B0-1 |

| 15 | 10 | Q43129 |

| 16 | 2 | DN0040M0-7 |

| 17 | 2 | DJ0003B0-1 |

| 18 | 2 | FM0002B0-5 |

| 19 | 2 | EB0001B0-2 |

| 20 | 2 | DJ0002B0-0 |

| 21 | 2 | CJ0040M0-2 |

| 21 | 2 | CJ0040A0-0 |

| 22 | 2 | FC0040M0-8 |

| 23 | 2 | 2SFN0054B0-3 |

| 24 | 4 | Q218B1225TF2 |

| 25 | 2 | BU0051M0-4 |

| 25 | 4 | Q2541040 |

| 26 | 1 | EN0063M0-3 |

| 1 | EN0064M0-4 | |

| 27 | 2 | CJ0049M0-2 |

| 27 | 2 | CJ0048M0-1 |

| 28 | 2 | EJ0044B0-7 |

| 29 | 2 | FK0043A0-7 |

| 29.1 | 2 | Q5211571 |

| 30 | 20 | FG0052B0-4 |

| 30 | 20 | FG0050B0-2 |

| 31 | 20 | CJ0057B0-0 |

| 32 | 2 | FK0044A0-8 |

| 33 | 2 | EH0002B0-9-B |

| 34 | 2 | GT0002B0-3 |

| 35 | 4 | D12-5711 |

| 36 | 4 | DQ0040B0-9 |

| 37 | 2 | D13-5711 |

| 38 | 4 | D23-5711 |

| 39 | 4 | MZ0040B0-7 |

| 39 | 4 | D22-5711 |

| 40 | 4 | ET0075A1-1 |

| 41 | 28 | AJ0007B0-2 |

| 42 | 28 | DJ0004B0-2 |

| 42 | 28 | FM0003B0-6 |

| 43 | 2 | GE0001M0-8 |

| 43 | 2 | GE0001M0-9 |

| 43.1 | 2 | C25-5711 |

| 43.2 | 2 | C18-5712 |

| 44 | 2 | BH0048S0-3 |

| 2 | BH0049S0-4 | |

| 44 | 2 | 2SBH0040S0-5 |

| 2 | 2SBH0041S0-6 | |

| 44.1 | 8 | DW0040B0-5 |

| 45 | 12 | H19-5711 |

| 46 | 12 | H20-5711 |

| 47 | 4 | C14-0301 |

| 48 | 2 | AP0049B0-4 |

| 48.1 | 4 | AP0050B0-6 |

| 49 | 2 | C15-0111 |

| 50 | 1 | AT0054M0-5 |

| 50 | 1 | AT0055M0-6 |

| 51 | 2 | Q151B1635TF2 |

| 52 | 2 | Q151B1685TF2 |

| 53 | 2 | AM0066M0-1 |

| 53.1 | On demand | ES0073B0-8 |

| ES0074B0-9 | ||

| 53.2 | 2 | AP0049B0-4 |

| 53.3 | 4 | C14-0301 |

| 53.4 | 2 | C17-5711 |

| 53.5 | 2 | C18-5712 |

| 57 | 1 | AB0050A0-1 |

| 1 | AB0051A0-2 | |

| 58 | On demand | C15-5715 |

| 59 | 2 | C16-0301 |

| 60 | 1 | CP0050A0-7 |

| 1 | CP0098A0-9 | |

| 1 | AL0042M0-4 | |

| 1 | BT0040B0-0 | |

| 62 | 6 | Q151B1845TF2 |

| 63 | 1 | GF0002B0-9 |

| 64 | 1 | AN0096M0-5 |

| 1 | AN0097M0-6 | |

| 65 | 1 | AN0094M0-3 |

| 1 | AN0095M0-4 | |

| 4 | BT0041B0-1 | |

| 66 | 8 | Q151B22240TF2 |

| 67 | 1 | GG0002B0-0 |

| 68 | 1 | Q618B06 |

| 69 | GJ0001B0-2 | |

| 70 | 1 | BD0049B0-3 |

| 1 | BD0050B0-5 | |

| 71 | 2 | AP0042B0-2 |

| 72 | 2 | GM0040B0-8 |

| 73 | 2 | AJ0003B0-8 |

| 14 | AJ0002B0-7 | |

| 73 | 16 | AJ0002B0-7 |

| 74 | 1 | AM0045S0-4 |

| 75 | 1 | AX0076A0-1 |

| 1 | AX0077A0-2 | |

| 76 | 4 | Q340B06 |

| 77 | 4 | Q68610 |

| 78 | 4 | Q218B571TF2 |

| 79 | 2 | AM0051M0-5 |

| 80 | 2 | A16-5711 |

| 81 | 2 | A15-5711 |

| 2 | CL0040B0-3 |

| NO. | Consumption | Parts number |

| 1 | 1 | DJ0058B0-1 |

| 1 | 1 | DJ0001B0-9 |

| 2 | 1 | 2SBY0049M0-5 |

| 3 | 1 | EH0001B0-8 |

| 4 | 1 | FL0003A0-4 |

| 5 | 1 | 2SEZ0077B0-9 |

| 6 | 1 | 2SEZ0076B0-8 |

| 7 | On demand | ES0057B0-0 |

| ES0058B0-1 | ||

| ES0059B0-2 | ||

| ES0060B0-4 | ||

| 8 | 1 | FK0046A0-0 |

| 9,22 | 1 | CC0076A0-2 |

| 9,22 | 1 | CC0073A0-9 |

| 9,22 | 2SCC0073A0-9 | |

| 10 | 1 | EB0043M0-9 |

| 11 | 4 | FK0048A0-2 |

| 12,23 | 4 | 2SAY0048A1-1 |

| 13 | 2 | Q150B1285TF2 |

| 14 | 4 | Q150B0820 |

| 15 | 4 | Q40308 |

| 16 | 2 | DC0040S0-2 |

| 17 | 4 | CF0041M0-9 |

| 18 | 4 | CD0041B0-0 |

| 19 | 1 | FB0041M0-8 |

| 20 | 2 | CE0042M0-9 |

| 21 | 2 | GC0044B0-2 |

| 24 | 16 | AJ0058B0-8 |

| 24 | 16 | AJ0004B0-9 |

| 25 | 1 | FK0047A0-1 |

| 26 | 1 | EB0042M0-8 |

| 27 | 1 | BF0046M0-3 |

| 28 | 1 | GC0045B0-3 |

| 29 | 1 | Q43170 |

| 30 | 1 | BF0047M0-4 |

| 31 | 1 | DD0041B0-7 |

| 1 | FR0041B0-3 | |

| 32 | 1 | Q180571 |

| 33 | 1 | 2SAU0046M0-7 |

| 34 | 1 | EJ0046B0-9 |

| 35 | 1 | 2SEJ0045B0-8 |

| 36 | 1 | DQ0047M0-7 |

| 37 | 1 | BF0048M0-5 |

| 38 | 1 | FE0041B0-0 |

| 39/40/41/42/43 | 1 | BA0047A0-7 |

Brand Culture

Packaging & Shipping

Working Principle

Function of gear transmission

1.Variable speed: By meshing 2 gears of different sizes, the speed of the gears can be changed. For example, the gearbox gear can reduce or increase the speed from the engine to meet the needs of the car;

2.Torque change: The meshing of 2 gears of different sizes changes the transmitted torque while changing the speed of the gears. For example, the car gearbox, the main reducer in the drive axle, can change the torque of the car;

3.Change direction: the power action direction of some vehicle engines is perpendicular to the driving direction of the vehicle. The transmission direction of power must be changed to drive the vehicle. This device is usually the main reducer and differential of the car.

Gear transmission has the advantages of high transmission efficiency, compact structure, reliable gear transmission, long service life and stable transmission ratio. Its transmission efficiency can reach 99%. Among the commonly used mechanical transmissions, gear transmission has high efficiency; its disadvantage is that compared with belt transmission and chain transmission, the manufacturing and installation accuracy of gears are high, and the price is more expensive. It is not suitable for transmission with too large distance between shafts.

Basic types of gear transmissions

| Gear drive | Plane gear transmission | Spur gear drive | Inner Meshing |

| External Meshing | |||

| Rack and pinion | |||

| Helical Gear Drive | Inner Meshing | ||

| External Meshing | |||

| Rack and pinion | |||

| Herringbone gear movement | |||

| Space gear transmission | Transfer intersecting motion | Spur gear | |

| Helical gear | |||

| Curved gear | |||

| Transfer staggered axis motion | Crossed helical gear transmission | ||

| Worm turbine | |||

| Hypoid gear |

Spur gear and helical gear

Spur gears enter and exit meshing along the whole tooth width at the same time. Its transmission efficiency is very high. Its disadvantages are poor stability, impact and noise.

The tooth meshing process of helical gear is longer than that of spur gear, and the number of teeth participating in meshing is also more than that of spur gear. Therefore, the helical gear transmission is stable, the bearing capacity is strong, and the noise and impact are small. The main disadvantage of helical gear is that the axial component force will be generated when the helical gear surface is subjected to the normal force, and the thrust bearing needs to be installed, which complicates the structure.

Lubrication of gear transmission

There is relative sliding and friction between gear transmission tooth surfaces, which will cause tooth surface wear, increase transmission power consumption and reduce transmission efficiency. Therefore, lubricant must be used to reduce wear and accelerate heat dissipation. This lubricant is gear oil. Different kinds of gears on the car are lubricated with different gear oils, which must not be added wrong. For example, automatic transmission oil and CVT transmission oil cannot be mixed.

Honor Certificate

FAQ

Q1. Are you a factory or trading company?

We are a factory integrating research, development, production and sales.

Q2. What are the advantages of your products?

We support product customization to meet customer needs for special products. We can strictly control the products from raw materials to production, processing, product quality inspection, delivery, packaging, etc., and provide customers with high-end products and the most advantageous prices.

Q3. How about products price?

We are a factory, all products are direct sale at factory price. For the same price, we will provide the best quality; for the same quality, we have the most advantageous price.

Q4. What is your terms of packing?

We have branded packaging and neutral packaging, and we can also do what you want with authorization. This is flexible.

Q5. How to guarantee your after-sales service?

Strict inspection during production, Strictly check the products before shipment to ensure our packaging in good condition. Track and receive feedback from customer regularly. Our products warranty is 365 days.

Each product provides quality assurance service. If there is a problem with the product within the warranty period, the customer can negotiate with us in detail about the related claims, and we will do our best to satisfy the customer.

Q6. How can I accurately buy the products I need?

We need accurate product number, If you can’t provide product number, you can send us your product picture, or tell us your truck model, engine name plate, and so on. we will

determine exactly what you need products.

Q7. Do you accept third party inspection?

Yes.we do

Q8. How about your delivery time?

Generally, it will take 3 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q9. What are your brand agency conditions and advantages?

After we CHINAMFG an agent in 1 city, we will not CHINAMFG a second company to protect the agent’s brand advantage and price advantage. And we will help the agent develop customers and solve all kinds of difficult and miscellaneous problems about products.

Q10. What is your terms of payment?

By TT or LC. We’ll show you the photos of the products and packages before you pay the balance.

| After-sales Service: | Support |

|---|---|

| Condition: | New |

| Application: | Ford Heavy Duty Truck |

| Samples: |

US$ 75/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles:

Planetary gears play a crucial role in hybrid and electric vehicle powertrains. In these vehicles, planetary gear sets are often used to combine the power from the internal combustion engine and the electric motor. The gear arrangement allows for seamless transitions between different power sources, enabling efficient energy management and optimized performance.

- Start-Stop Systems:

Start-stop systems, which automatically shut off the engine when the vehicle is stationary and restart it when needed, often incorporate planetary gears. These gears help engage and disengage the engine from the drivetrain smoothly, ensuring a quick and seamless transition between the engine’s off and on states. Planetary gears contribute to the overall efficiency and reliability of start-stop systems.

- Power Steering:

Some power steering systems in automobiles utilize planetary gears to provide assistance in steering. These gears help amplify the driver’s input torque, making steering easier and more responsive. The compact size and high torque capacity of planetary gears make them suitable for power steering applications.

In summary, planetary gears find extensive use in automotive applications, including automatic transmissions, four-wheel drive systems, hybrid and electric vehicle powertrains, start-stop systems, and power steering. Their compact size, high torque capacity, and ability to achieve multiple gear ratios make them well-suited for these applications, providing efficient power transmission, improved performance, and enhanced driving experience in vehicles.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature: